tecodrive develops, manufactures and distributes products for the metal forming industry. The first product fleXfeed is the contactless feed for metal forming machines. fleXfeed is faster, consumes less energy and results in lower maintenance costs than traditional roll or gripper feeds. At the same time it does not damage the metal strip.

fleXfeed

fleXfeed: no jamming, no rolling out, hight speed, low operating costs

DEVELOPEMENT

THE REVOLUTION

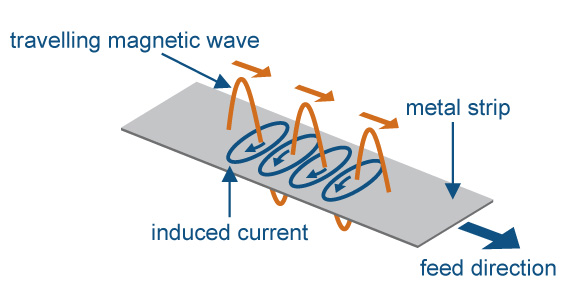

The contactless press feed is based on the principle of magnetic attraction and / or repulsion. Two stators are arranged opposite each other. These produce a traveling magnetic wave in the metal strip in the gap between the two motors.

In the case of electrically conductive, non-magnetic materials (e.g. aluminium, copper), the electric currents that are induced in the metal strip by the motors lead to – alongside the feed force – repulsion from the two motors. In this way the metal strip is held in the middle of the guide channel and moved without jamming. In the case of magnetic materials (e.g. steel) the attractive forces of the two motors cancel themselves out, which also results in contactless transport.

LOWER COSTS, BETTER PARTS

| CONTACTLESS PRESS FEED | USER BENEFITS |

|---|---|

| Metal strip is fed contact-free | Metal strip and also coated, printed and stamped materials are not stressed or damaged |

| 2x higher feed force ans therefore double speed | Higher output and more time for forming |

| Straightforward design with few moving parts without additional units | Lower maintenance costs, less downtime, lower energy consumption, long lifetime |

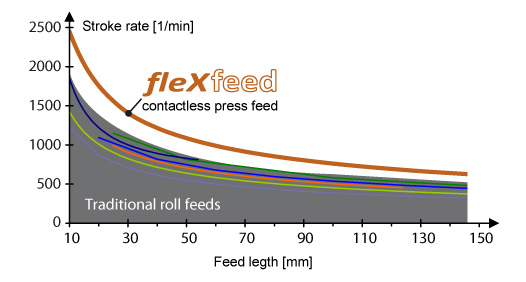

COMPARISON OF fleXfeed WITH CONVENTIONAL PRESS FEEDS

THE PERFORMANCE CLASSES OF THE CONTACTLESS PRESS FEED fleXfeed

Materials: all electrically conductive metals

Strip thickness: up to 3,0 mm

Strip width: 10 – 450 mm

Feed power: up to 4000 N

Feed length: unlimited

Accuracy: +/- 0,01 mm

Acceleration: up to 800m/s²

THE RIGHT PRESS FEED FOR YOUR NEEDS

In principle, the contactless press feed can be built in any configuration. If the right model for your application is not listed, please contact us.

| Model | Material width (mm) | Material thickness (mm) |

|---|---|---|

| fleXfeed 2061 | 10 – 60 | 0,1 – 0,8 |

| fleXfeed 3071 | 20 – 70 | 0,3 – 1,0 |

| fleXfeed 311 | 20 – 100 | 0,3 – 2,0 |

| fleXfeed 4251 | 20 – 250 | 0,3 – 2,0 |

| fleXfeed 6251 | 20 – 250 | 0,3 – 3,0 |

| fleXfeed 831 | 50 – 300 | 0,3 – 3,0 |